Background

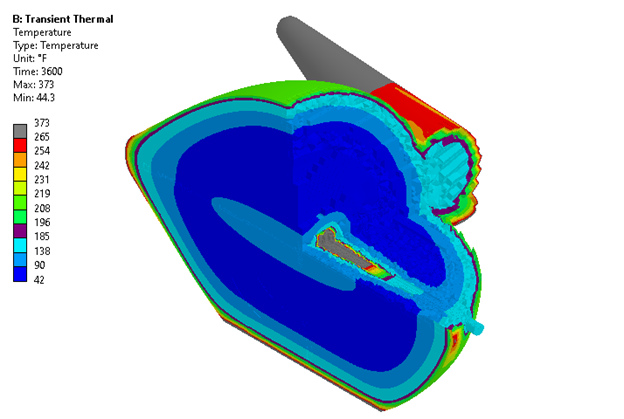

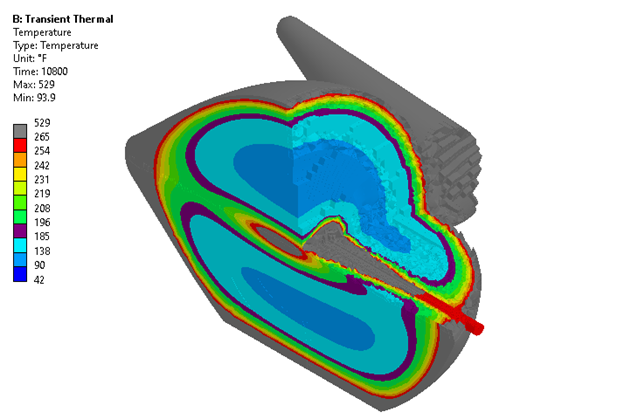

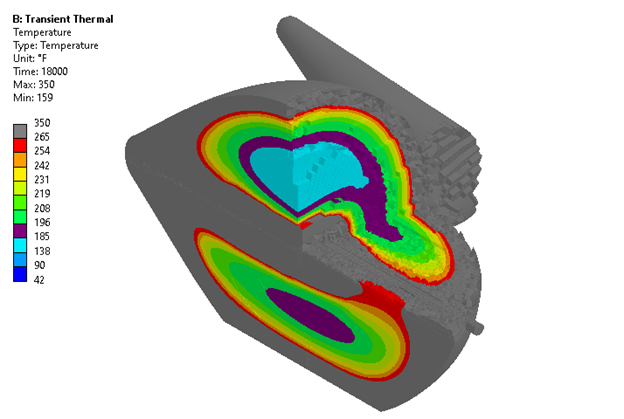

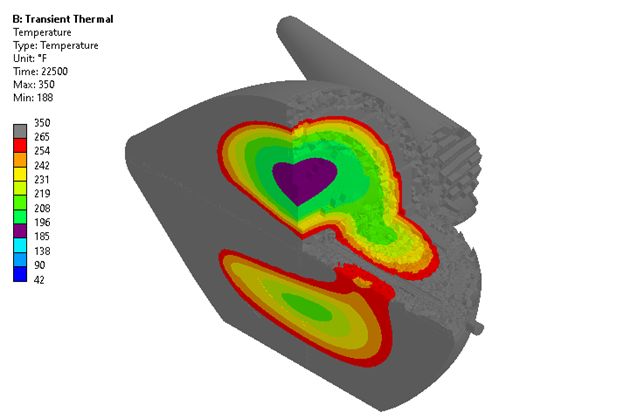

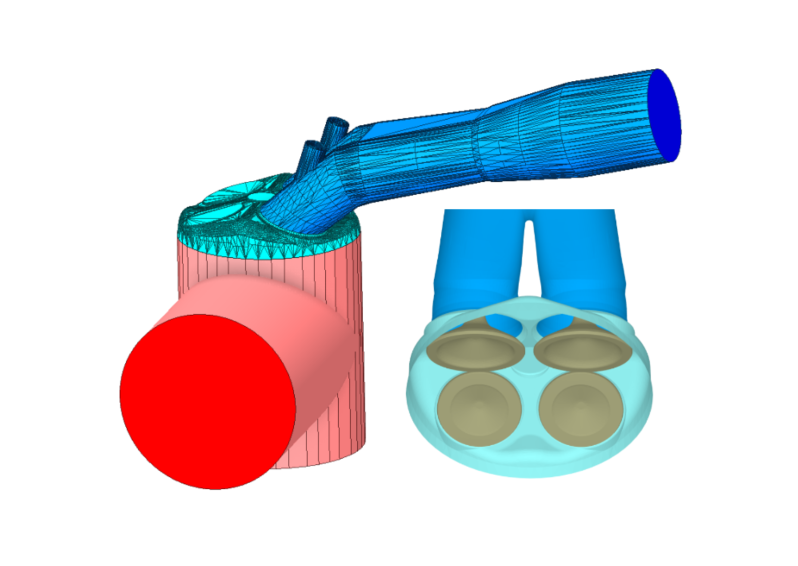

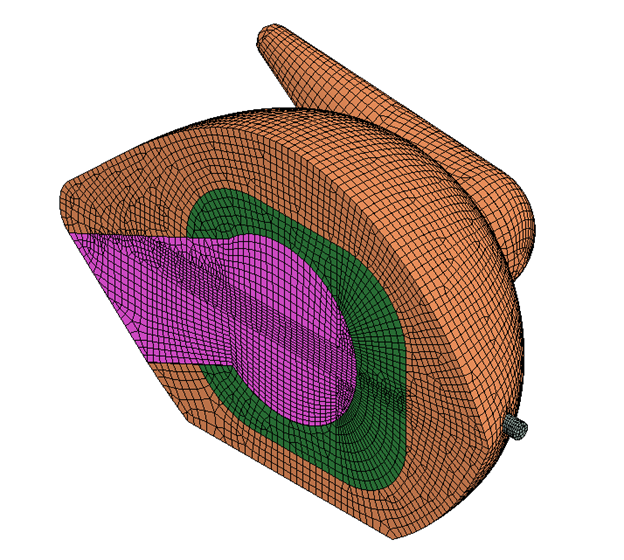

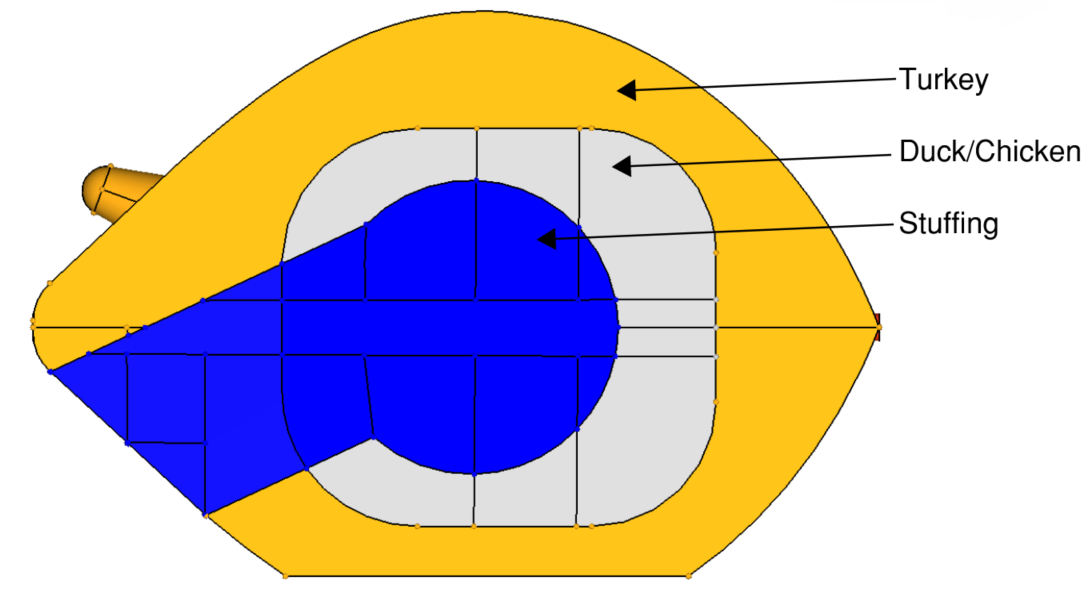

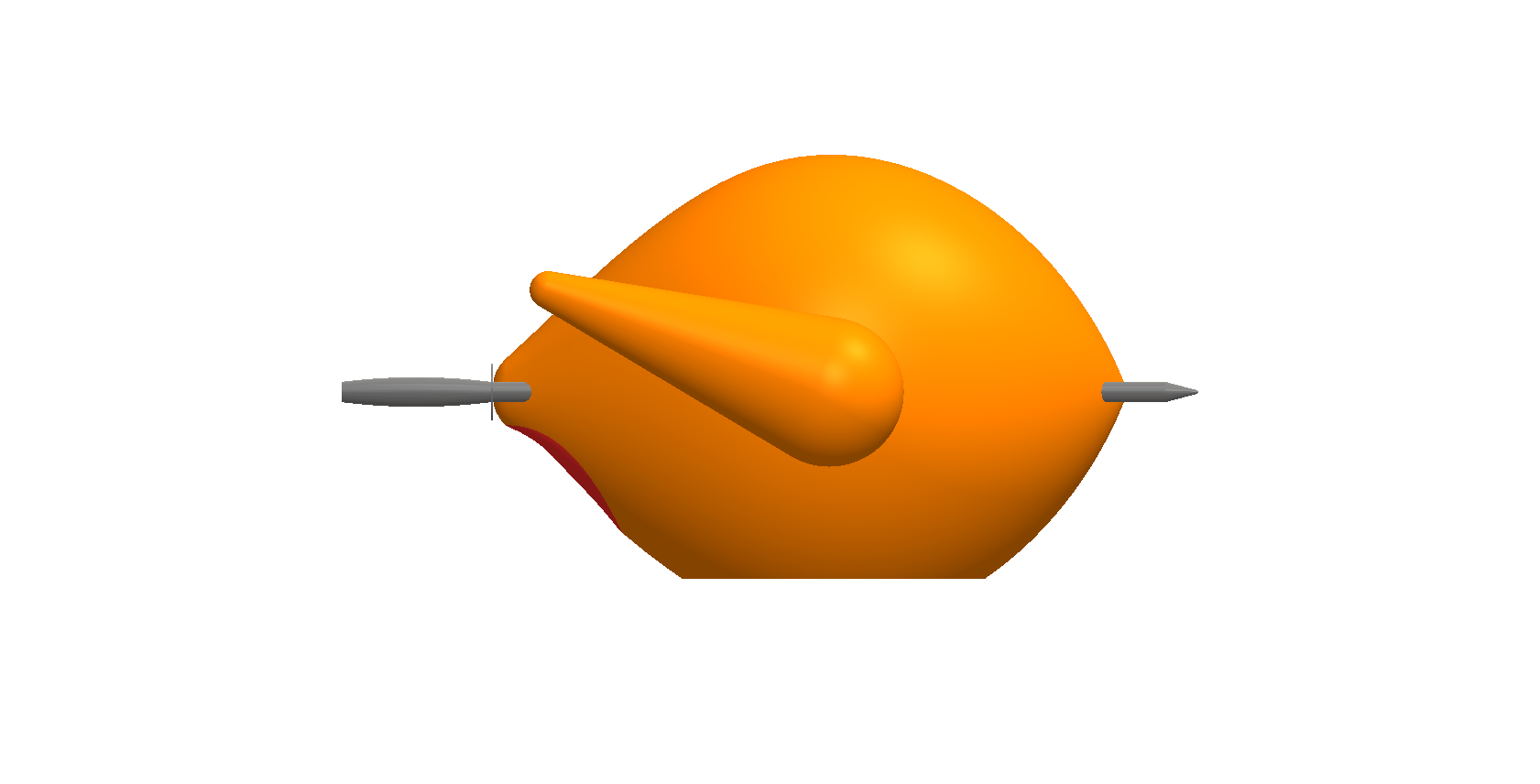

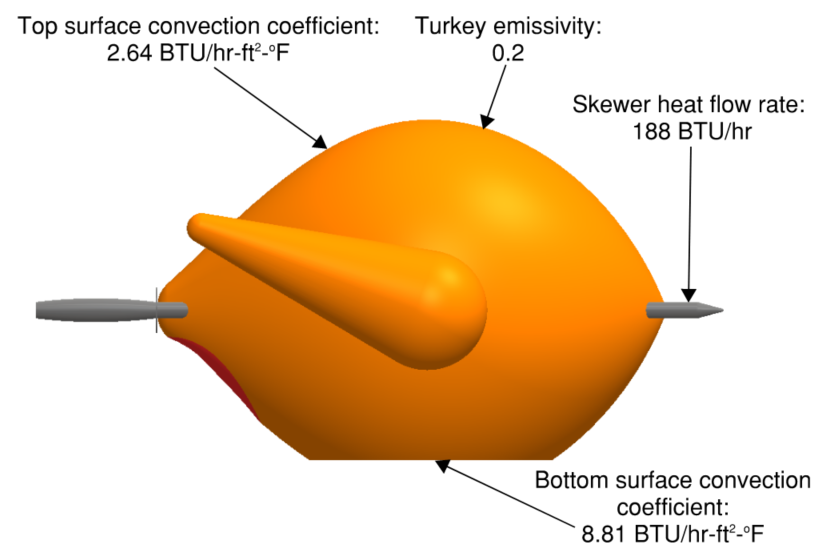

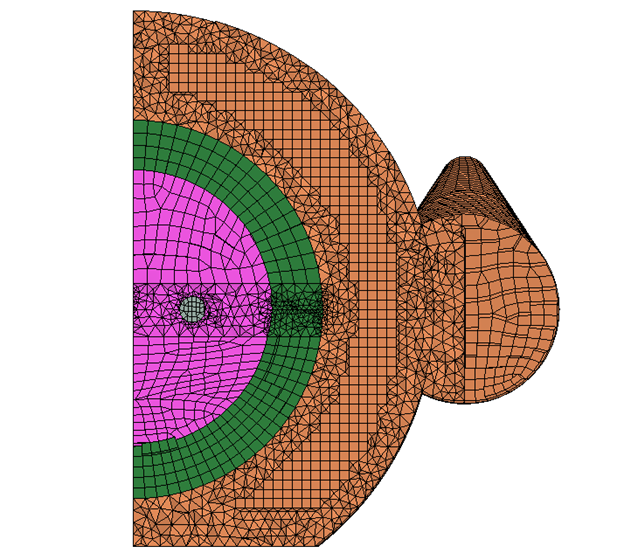

The final project for Cooper Union’s Introduction to Computer Aided Engineering (CAE) course involved teams of 4 students analyzing the cooking process of a turducken using a convection oven and 2 resistive heating skewers. The turducken consists of 3 layers: an outer layer of turkey, a middle layer of a homogeneous mixture of duck and chicken, and an inner layer of team-selected stuffing. The objective was to minimize the cooking time required to fully cook the turducken (minimum temperature of 185°F) while also minimizing the percentage of burnt turducken (temperature exceeding 265°F). We performed a transient thermal analysis on the turducken using ANSYS Workbench and validated our results with simplified hand calculations.

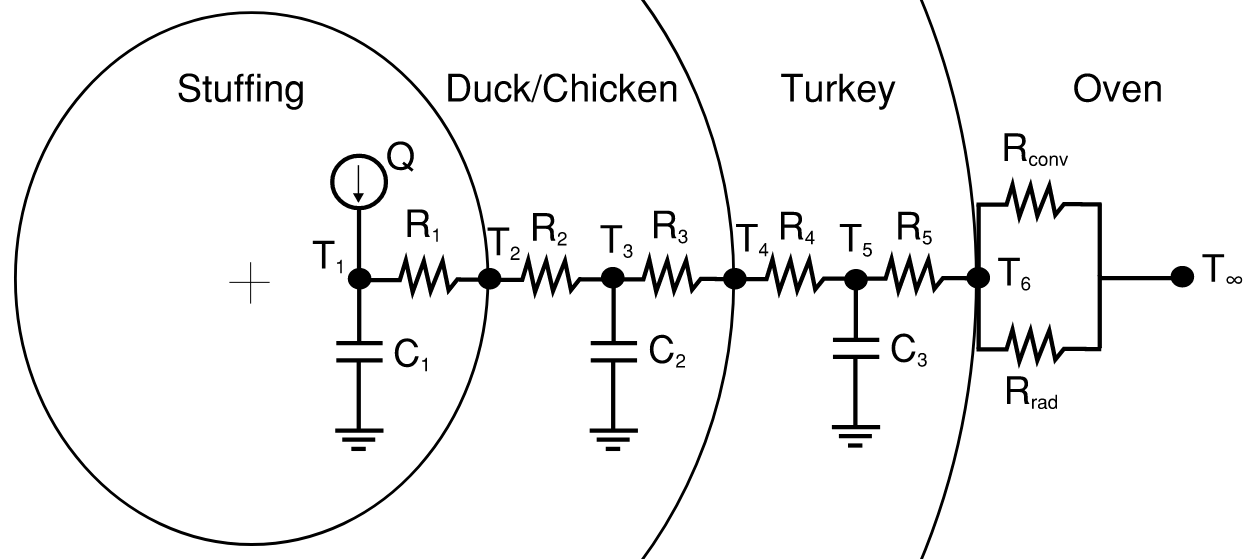

Turducken thermal circuit.

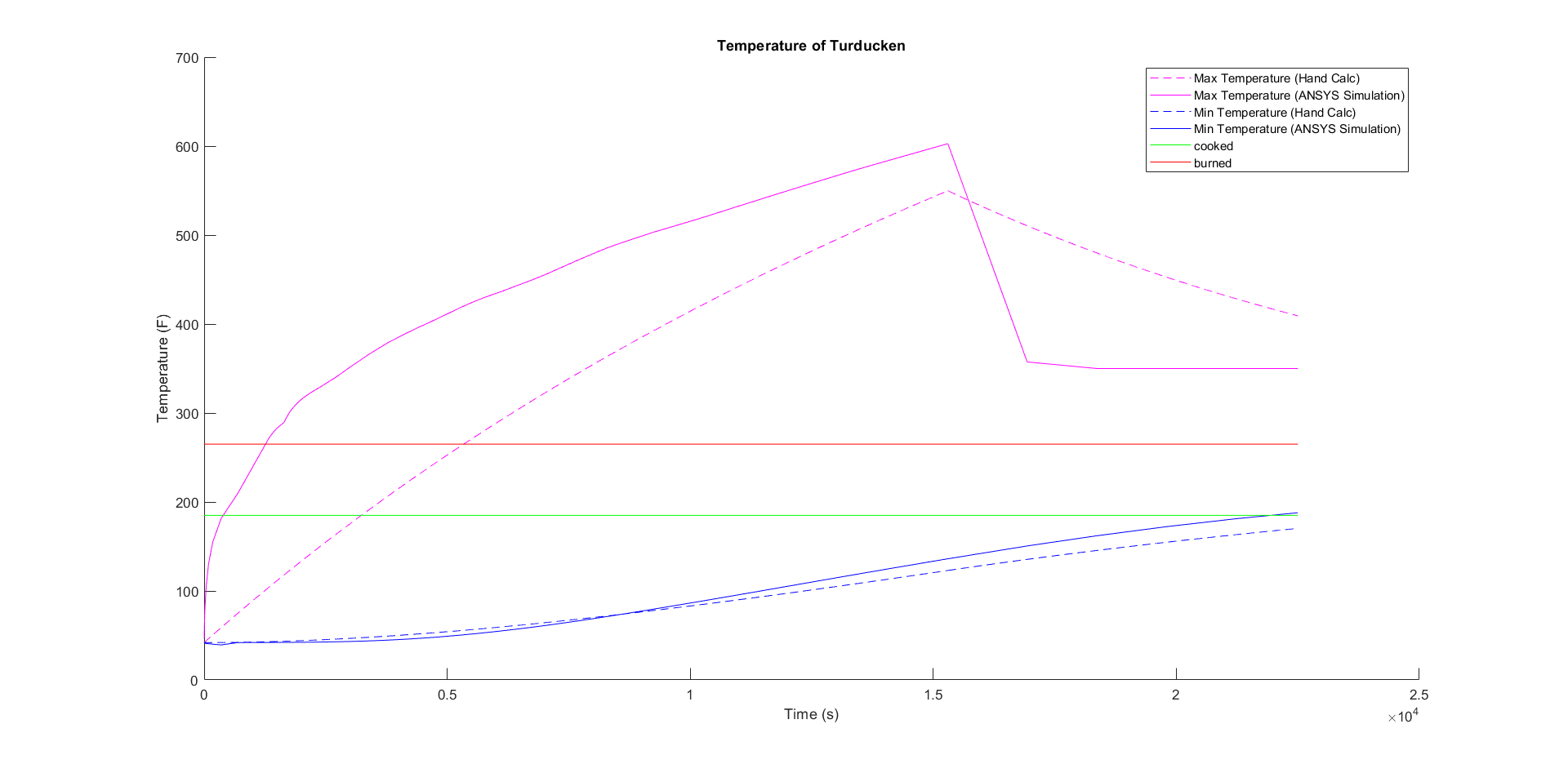

Turducken thermal circuit. Hand calculation results compared to analysis results: solid lines represent ANSYS simulation results, and dashed lines represent hand calculation results.

Hand calculation results compared to analysis results: solid lines represent ANSYS simulation results, and dashed lines represent hand calculation results.